There has been an explosion of engineering disciplines and subspecialties in the past fifty years. And because engineering and the creativity it requires is a team effort in many ways, there are careers for engineers of varying personal capability. Just as a basketball team needs a center to support the point guard, or an orchestra needs the third-seat cellist to support the horn and trumpet, every engineering team can benefit from the contributions of its members. In fact, The Stemwinder would argue that there are engineering disciplines which, by virtue of their range of demands for theoretical versus applied technology, draw on different skills that students bring to their education and career, and matching skills and interests to the choice of major is a part of ‘fit’.

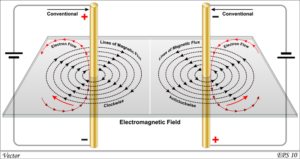

What does engineering look like for the B student, or conversely what are the ‘hardest’ engineering disciplines? The primary area which that student should consider is their mathematical abilities. To be more specific: Some engineering requires highly conceptual math which may be hard to visualize; an example is the application of the Maxwell-Faraday equation which states that the voltage induced in a closed circuit is proportional to the rate of change of the magnetic flux it encloses. Simple, right?

What does engineering look like for the B student, or conversely what are the ‘hardest’ engineering disciplines? The primary area which that student should consider is their mathematical abilities. To be more specific: Some engineering requires highly conceptual math which may be hard to visualize; an example is the application of the Maxwell-Faraday equation which states that the voltage induced in a closed circuit is proportional to the rate of change of the magnetic flux it encloses. Simple, right?

Or the branches of mechanical and aerospace engineering which deal with Computational Fluid Dynamics: The calculation of how mixed fluids and gases, which are compressible, flow around solid objects, and can be supersonic – each of these is highly

non-linear due to the interactions of gas, liquid, and solid and the different properties of each. Electric fields and computational fluid dynamics both require math with multiple partial differential equations just to get started!

By now, you will have observed the pattern: if you can actually see an engineering discipline’s results, and the math that the discipline uses is relatively straightforward, then its demands on the student may be a better fit for the “B” student’s skills and interests. What are some of these disciplines and where can the reader learn more?

One of the earliest engineering discipline which focused on visualization of a product is industrial engineering. The IE finds ways to eliminate wastefulness in production processes. They devise efficient systems that integrate workers, machines, materials, information, and energy to make a product. A classic study of the process was carried out at the Western Electric Hawthorne manufacturing facility in the 1930’s and attempted to measure the effect on worker productivity of changes in the manufacturing environment. An important, and still relevant, outcome was the understanding of the social rather than purely scientific nature of the study of work. Some credit Henry Ford with creating the first assembly line for automobiles – the model T.

The Department of Industrial and Systems Engineering, at the University at Buffalo, has programs that span a wide array of disciplines, from pedestrian and traffic management to health care. A modern application of industrial engineering is in the Toyota Production System – which optimizes the manufacture of automobiles by “the complete elimination of all waste”. The BS degree in industrial and systems engineering at SUNY Binghamton prepares graduates for designing, developing, and managing complex processes and systems involving people, information, equipment, and financial and material assets, with special emphasis on using probabilistic methods, design of experiments, and simulation. Other areas of study for industrial engineers include time-motion studies and ergonomics; in their capstone project, IE students at Oregon State University can work on improving the efficient or ergonomics of machinery on a factory floor. Industrial engineers thus get to interact with people and their work environment.

Another kind of engineering which has been around a long time is materials engineering. If you were wide awake during history class you will remember hearing about the Bronze Age and Iron Age. The Bronze Age, from 3300 to 700 BC, was a period when ancient cultures learned to spelt copper and tin and mix them together along with other elements. During the Iron age from 1200 BC to about 800 AD, societies developed the ability to turn iron ore into usable iron of varying hardness and toughness. The materials engineer of today has turned this into an advanced pursuit of understanding; according to the US Department of Labor, materials engineers develop, process, and test materials used to create a wide range of products, from computer chips and aircraft wings to golf clubs and biomedical devices. They study the properties and structures of metals, ceramics, plastics, composites, and nanomaterials to create new materials that meet certain mechanical, electrical, and chemical requirements. Materials engineering is often called materials science, and often taught in the college of mechanical engineering. Some of the subspecialties in this major include ceramics, metallurgy, plastic and polymers, and nano manufacturing. One of The Stemwinder’s favorite undergraduate engineering classes was fracture mechanics, where the class studied how things break – including the Charpy Impact Test which drops a great big hammer on a sample and measures the cracks.

Another kind of engineering which has been around a long time is materials engineering. If you were wide awake during history class you will remember hearing about the Bronze Age and Iron Age. The Bronze Age, from 3300 to 700 BC, was a period when ancient cultures learned to spelt copper and tin and mix them together along with other elements. During the Iron age from 1200 BC to about 800 AD, societies developed the ability to turn iron ore into usable iron of varying hardness and toughness. The materials engineer of today has turned this into an advanced pursuit of understanding; according to the US Department of Labor, materials engineers develop, process, and test materials used to create a wide range of products, from computer chips and aircraft wings to golf clubs and biomedical devices. They study the properties and structures of metals, ceramics, plastics, composites, and nanomaterials to create new materials that meet certain mechanical, electrical, and chemical requirements. Materials engineering is often called materials science, and often taught in the college of mechanical engineering. Some of the subspecialties in this major include ceramics, metallurgy, plastic and polymers, and nano manufacturing. One of The Stemwinder’s favorite undergraduate engineering classes was fracture mechanics, where the class studied how things break – including the Charpy Impact Test which drops a great big hammer on a sample and measures the cracks.

Civil Engineering is another engineering sector that has strong practical implementation aspects. A civil engineer will often find themselves at the site of a bridge, dam, tunnel, or calculating how many truckloads of gravel, sand, rebar, and concrete will be needed to create a structure. A civil engineer will use calculus in studying basic design concepts, such as the bending of a beam or the frequency of earthquake-induced shaking of a building; but the CE will also need to work closely with construction specialist, materials engineers, and project schedulers to get the right kind of material in the right place and correct sequence. A team of civil engineers, working with many other disciplines, recently completed construction of the Nigliq Channel bridge near the Arctic coast of Alaska:

As you can see, the amount of material estimating, sequencing, and planning necessary to get this bridge built – and done during the winter construction periods – is a testament to the practical nature of the civil engineer’s job.

Another hands-on major leading to a career using the degree is Packaging Engineering. The packaging engineer works in a multi-disciplinary field that draws on chemical, industrial, materials, and mechanical engineering in order to design and create boxes, cartons, bottles, and other packing materials. Since almost everything we buy is delivered in some kind of package – from a soda bottle to a hi-def television – the need for custom packaging is everywhere. If your high school has ever held an egg-drop contest (like this one at Colorado School of Mines), you know how important a good drop-resistant package can be. There are several colleges that have majors or concentrations in packaging engineering, including Rutgers, Michigan State, Rochester Institute of Technology. And Indiana State offers a packaging engineering technology degree. Careers in packaging engineering can be with manufactures or with companies that transport goods. Here you can see the packaging lab at UPS testing some crush-resistant and impact resistant packaging materials:

These are some of the engineering degrees, and careers, that can be a successful path for the student who is good, but not great at math, whose interests lean more towards practical hardhat and laboratory experiences than to conceptual and theoretical applications, who like to see what they’ve done and to engage with team members who may be highly skilled technical workers. And fortunately there is a place for many kinds of engineers.